Gas and air treatment systems

Our company designs and manufactures a wide range of gas treatment equipment, which can include the following technological processes: purification, drying, heating, compression, cooling, gas reduction. Our engineers can combine these processes in the process flow diagrams developed to provide the optimum equipment design to meet the customer's requirements.

Barrier nitrogen, tooling, separation and cooling air treatment systems.

The most important component of any production plant, shop, workshop is a pneumatic system. Applied application of the system is quite wide - from valve actuators and providing purging of equipment and pipelines to air cooling and operation of pneumatic tools.

LLC "Omni Technologies" carries out design, manufacture and supply of units and systems of air and nitrogen preparation for various production processes, providing the necessary parameters of air/nitrogen preparation.

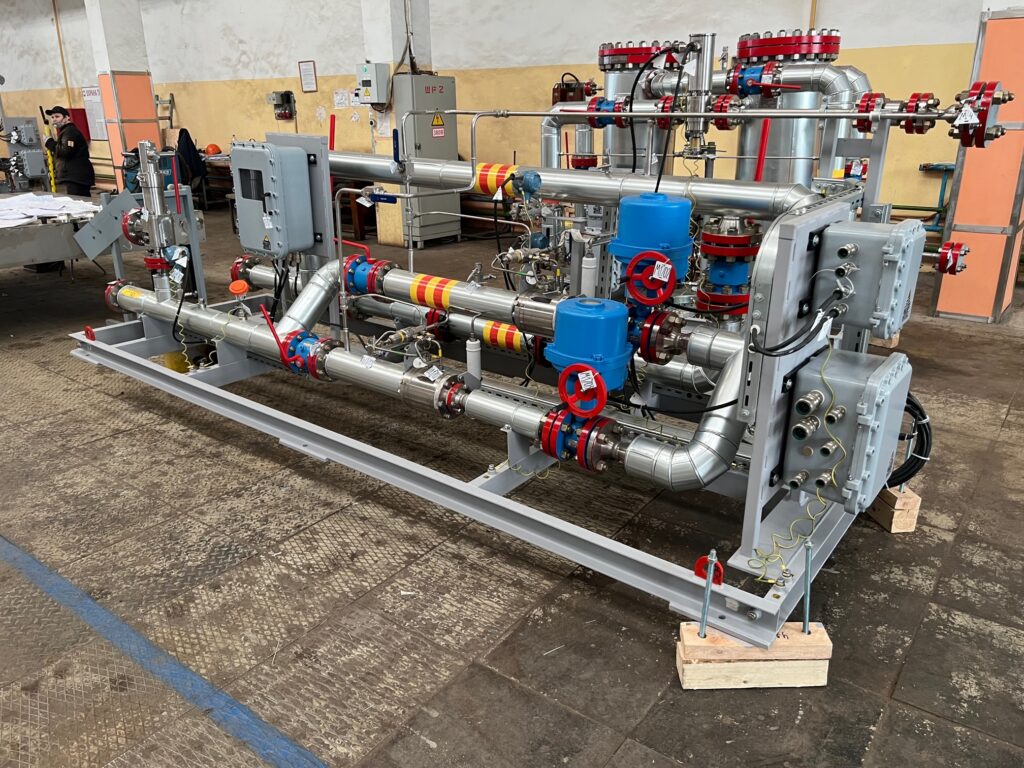

Fuel gas treatment systems

At compressor stations of gas pumping as a standard drive of gas pumping units gas turbine engines are used. To ensure smooth operation, the fuel gas for the engines must be purified to the required parameters. Our range of equipment includes various models of fuel gas treatment units and systems of both outdoor and aggregate (in-house) design.

Buffer gas treatment systems

At compressor stations of gas pumping unit compressor dry gas dynamic seals use mainline natural gas as a working body. Due to increased requirements to the purity of this gas, our company offers blocks and systems for buffer gas treatment with purification fineness up to 0.5 microns. The equipment is produced both in outdoor and in aggregate (in-house) versions.